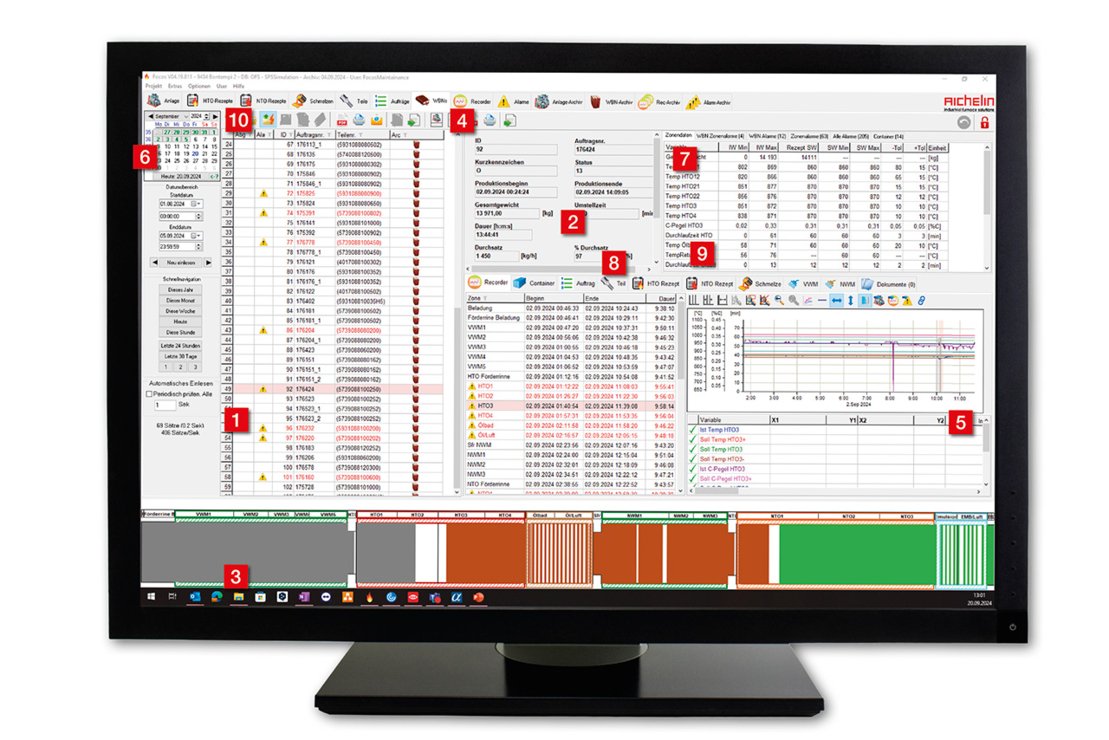

The operation of heat treatment plants can generally be divided into two areas: Plant control (programmable logic controller) incl. HMI (Human Machine Interface) and the process controlsystem.

The FOCOS 4.0 process control system developed by AICHELIN provides a clear overviewof your production processes with central real-time data and optimized evaluations. It simplifiesyour analyses with user-friendly dashboards and automated reports. The software alsoenables seamless integration of your furnace system data into your IT infrastructure allowingyou to make informed decisions faster and more efficiently.

Combined with the AICHELIN system controls (PLC / HMI), which ensure high availability,flexibility, and safety of your systems, you can create a comprehensively optimized and safeproduction environment. The modular system control of your AICHELIN plant can be supplementedby the FOCOS 4.0 process control system on request.

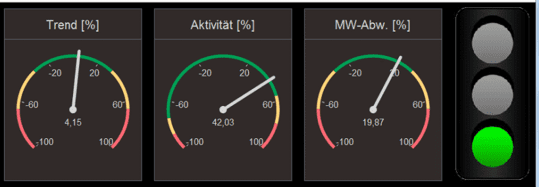

The Condition Monitoring (CM) module in FOCOS 4.0 offers an effective solution for predictingand preventing unplanned failures of critical plant components. Integrated into the statisticalprocess control, the CM module visualizes anomalies and enables early preventive maintenancemeasures to avoid expensive downtimes. By continuously monitoring vibrations, temperatures, and current consumption, creeping changes in condition are detected earlyon and visualized.

A key advantage of the CM System is based on the PF interval: It uses the advance warningtime between the first signs of a deviation (“Potential Failure”) and the actual failure (“Failure”).This early warning system enables proactive maintenance, increases system reliability andminimizes unexpected downtime.

The CM cockpit provides clear, easy-to-understand monitoring information. It consists ofthree main displays:

A status traffic light provides an overview of the status of the variables at a glance. Theworst of the three values determines the displayed traffic light color (green, yellow or red) and thus allows for a quick assessment. This clear visual representation makes it possibleto recognize immediately when preventive measures are required to avoid major failures.

The MultiEdit function offers maximum flexibility: When MultiEdit is switched off, you edit asingle line precisely, while multiple lines can be selected. If MultiEdit is activated, you canedit several lines at the same time to save time - ideal for quick, repeated changes suchas adding comments or adjusting settings. This makes work much easier, especially withlarge amounts of data.

Another advantage is that copying and deleting multiple lines is always possible, regardlessof the mode. In the order table, you can adjust the order of individual lines using drag &drop when MultiEdit is deactivated. When MultiEdit is activated, you benefit from the optionof editing or deleting several lines simultaneously - saving valuable time.

With version history for recipes, programs and parts tables, you always have an overviewof all changes. Every saved change is automatically recorded as a new version so that youcan access previous versions at any time. This not only provides transparency, but alsosecurity, as all changes are fully documented.

The different versions of an object can be conveniently displayed via the table pop-upmenu. An additional tab shows the history, highlighting differences between versions. Thismakes it easier to identify changes quickly. If a new version of a linked object is created(e.g. HTO recipe), the associated object is automatically versioned - a major advantagefor the traceability of linked data. You can also adjust the filter to display either only theversions of a specific object or all versions in the history.

Do you have any questions about the AICHELIN control systems for your system type? We will be happy to help you with the right information and contacts. Simply send us your questions using the form below and we will take care of your request as soon as possible.

Focos 4.0 Process Control System

(PDF |

2.37 MB |

ger-DE )